Figure G4 Part 7 Casting File We select the Inventor icon in the upper left corner of the Inventor 2012 window and we select Save As from the drop down menu. Casting egr 403 group 7 brian jacobs michael mayer noah winsor matthew yeseta proposal perform cost analysis on 2 different processes machining vs.

The Casting Process Of The Enclosed Switchgear Outer Body Casting Download Scientific Diagram

When it comes to the argument between die casting and CNC machining the answer is not always immediately clear.

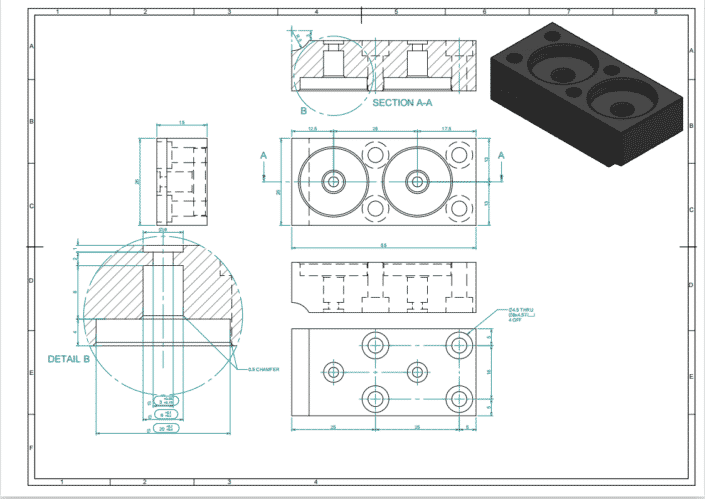

. Casting Vs Machining Drawing. Hence any mistake in a production drawing will result in loss of time money and decreased productivity. This technical drawing shows the machine parts assembly using joining by threaded fasteners.

The Single Source Advantage. Overview of Machining Versus Cast Molding. While the hot chamber die-casting machine average 400900 times per hour high production efficiency.

In this blog post we will talk about the difference between casting and diecasting. If the finish symbol is used on the field of the drawing stock will be allowed for machining. Forging is the application of thermal.

Turn any sketches with machining geometry on then derive the machined version. We name the file Part 7 machining and push the Save button. Difference between casting vs forging.

Assembling joining of the pieces is done by welding binding with adhesives riveting threaded fasteners or even yet more bending in the form of a crimped seam. I also provided a table summary to. Or if there is any higher surface finish requirement machining is also needed to meet the drawings specification.

General cold chamber die-casting machine average 5090 times per hour. Structural steel and sheet metal are the usual starting materials for fabrication along with the welding wire flux and. We can supply stainless steel investment castings in various grades including 304L 316L 17-4ph 2205 etc.

With CNC machining engineers can model machine test and remodel prototypes without going back to the drawing board. The cast surfaces are located to the cast. Forging Drawing vs Machining Drawing.

Jan 30 2012 RE. The casting drawing should not indicate machining data. Machining Drawing dgallup Automotive 27 Jan 12 1126 The way I approach this from a modeling perspective is to make the casting model first merge the casting into my machined part model as the first solid and then make only material removal features in.

In some eras and in some industries the foundry was given the drawing of the finished part and they create a drawing of what the finished casting should look like and of course the pattern needed to create the cast part. Casting can be considered the great-granddaddy of all the processes as it involved smelting the process of obtaining the pure forms of metal from mined ores. Tmoose Mechanical 27 Jan 12 1245.

In fact there are many manufacturing processes that are actually made more efficient when CNC machining follows die casting. Share your experiences on converting to castings below or reach out to us for how we can help convert your first part. Deep drawing die is a die that uses the die to pull the material into an open hollow part or make the hollow part further change its shape and size.

Die casting may be more cost-effective in terms of volume but CNC machining offsets the die cost. The 18th and 19th Centuries the era we call the Industrial Revolution saw great advances in forging and casting technologies as well as the subtractive process we call machining. Precision CNC machining can produce parts with a tolerance of - 00002 whereas precision aluminum die casting is more like 0002.

Casting determine which process is economically benificial based on net present worth analysis request for quote 4 fin impeller personal watercraft application 6061-t6 aluminum. Figure G4 Part 7 Casting File We select the Inventor icon in the upper left corner of the Inventor 2012 window. CFS Foundry is the top custom stainless steel casting and machining manufacturer in China.

Ideal Applications for Machining and Molding. In the casting sketch both the casting and the machining. If this level of precision is extremely important to your application CNC machining may be the better option for you.

CNC machining uses computer software to control machine tools that cut complex 2D and 3D shapes out of blocks of material. Casting and Machining are Complementary processes to each other in investment casting. While in the molten or liquid state it is poured into a mold or vessel to create a desired shape.

Furthermore casting tends to be cheaper than diecasting. Casting uses metals and other materials such as epoxy plastic concrete and clay while diecasting uses non-ferrous metals such as zinc aluminum tin and magnesium. Making large design changes to.

Usually a CAD drawing or other digital representation of the desired part is created and then the drawing is translated into instructions eg speeds locations and. Machining sensitiviy analysis for both options change in total income had the most effect 20 change in income resulted in 30 change in present value highlow for casting electricity was significant as well larger amount higher significance salvage least signigficant sensitivity analysis conclusion we. We see our casting drawing and we will save the file as Part 7 machining.

Machining Drawing - Mechanical engineering. Casting is the process where metal is heated until molten. Jan 30 2012 RE.

The cast to machine workflow works great for Inventor but is backwards to the normal design workflow. Figure G5 Part 7 Machining We then can close. Aluminum CNC Prototype Aluminum Machining.

Forging is the application of thermal and mechanical energy to steel billets or ingots to cause the material to change shape while in a solid state. Machining Drawing dgallup Automotive 27 Jan 12 1126 The way I approach this from a modeling perspective is to make the casting model first merge the casting into my machined part model as the first solid and then make only material removal features in the machined part. A method around this dilemma is to start them both at the same time.

When doing so there are two major things that you must consider cost and efficiency.

15 Detail Drawings Permission Granted To Reproduce For Educational Use Only Explain Terms And Standards Related To Various Types Of Drawings Used In Ppt Download

Machinist Drawings Building Codes Northern Architecture

Cast Iron Product Drawing And Renderings Help Facilitate The Iron Casting Purchasing Process

Solved 2 A Choose An Appropriate Casting Process Chegg Com

Technical Drawing For Cnc Machining Runsom Precision

The Bearing Bracket Casting Part Drawing Download Scientific Diagram

0 comments

Post a Comment